MULTI-FUNCTIONAL ENERGY RECOVERY SYSTEMS

In order to achieve the desired set point temperatures, it is sometimes necessary to supply added cooling or heating to the system. This can be done by means of plate heat exchangers in the water/glycol circuit, which is advantageous in terms of air pressure drop and space constraints.

SYSTEMS WITH ENERGY AND ECONOMIC ADVANTAGES

It is possible that, even with very efficient energy recovery systems, the recovered energy is not sufficient to reach the supply air temperatures. In these cases, supplemental cooling or heating is supplied to the system. Depending on the requirements and design, this can be done in different ways.

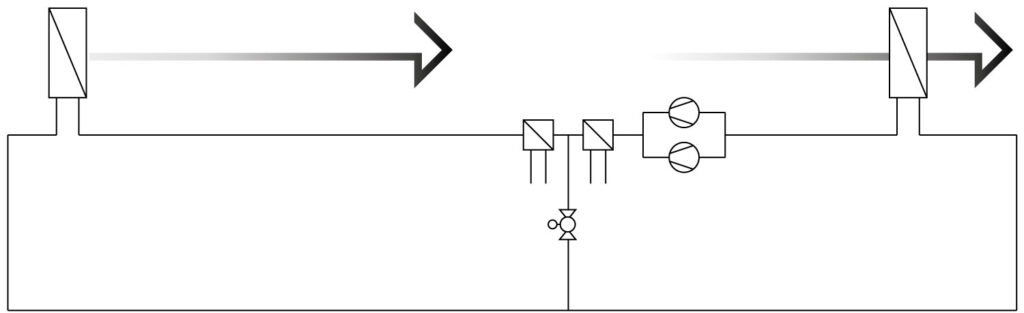

On the air side, this can be implemented by means of a downstream heating coil or cooling coil. An alternative is to introduce heat or cold into the water/glycol circuit using a plate heat exchanger (see schematic diagram below). By doing this, considerable space can be saved in the air handler, since both the heating coil and cooling coil are eliminated. The air pressure drop from these coils is also eliminated. As a result, operating costs are reduced because the supply air and exhaust air fans have lower power requirements.

HIGH ENERGY EFFICIENCY

To achieve high energy efficiency, it is imperative to take the input of heat or cold into account when determining the optimum circulation rate. By simply “optimizing efficiency”, i.e., controlling the circulation rate as a function of the variable air volume flow rates, it is not possible to achieve high efficiency. This is especially true in the case of multi-functional energy recovery systems. As a result, the energy efficiency of the system is subpar. Optimal regulation of a multi-functional ERS uses the performance mapping of the heat exchangers as well as the characteristics of the circulation pump and the valves.