KONVEKTA CONTROLLER

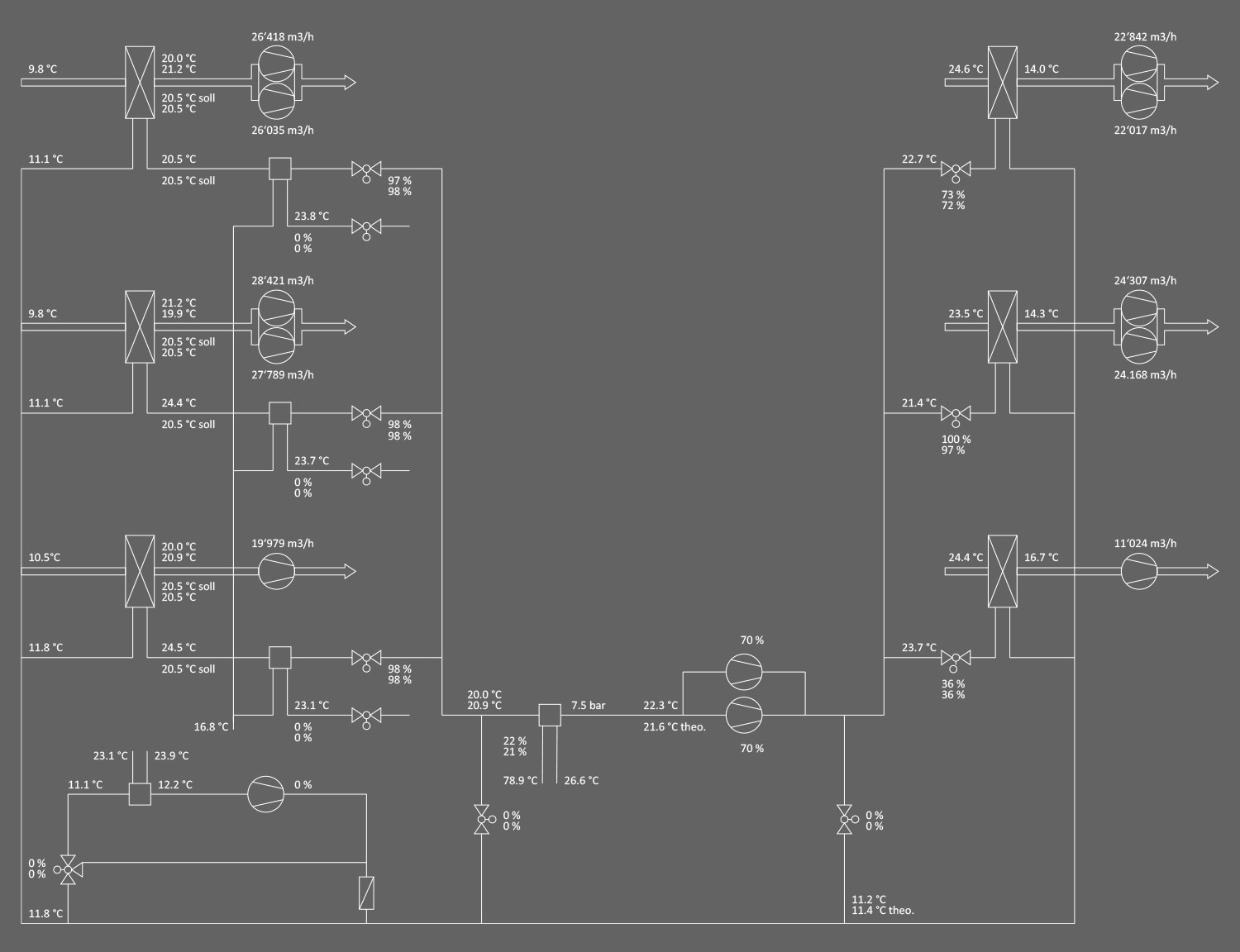

The Konvekta Controller optimally controls the entire ERS under normal and part load conditions.

OPTIMAL OPERATION OF THE ENERGY RECOVERY SYSTEM FOR MAXIMUM RETURN ON INVESTMENT.

DATA-BASED DESIGN

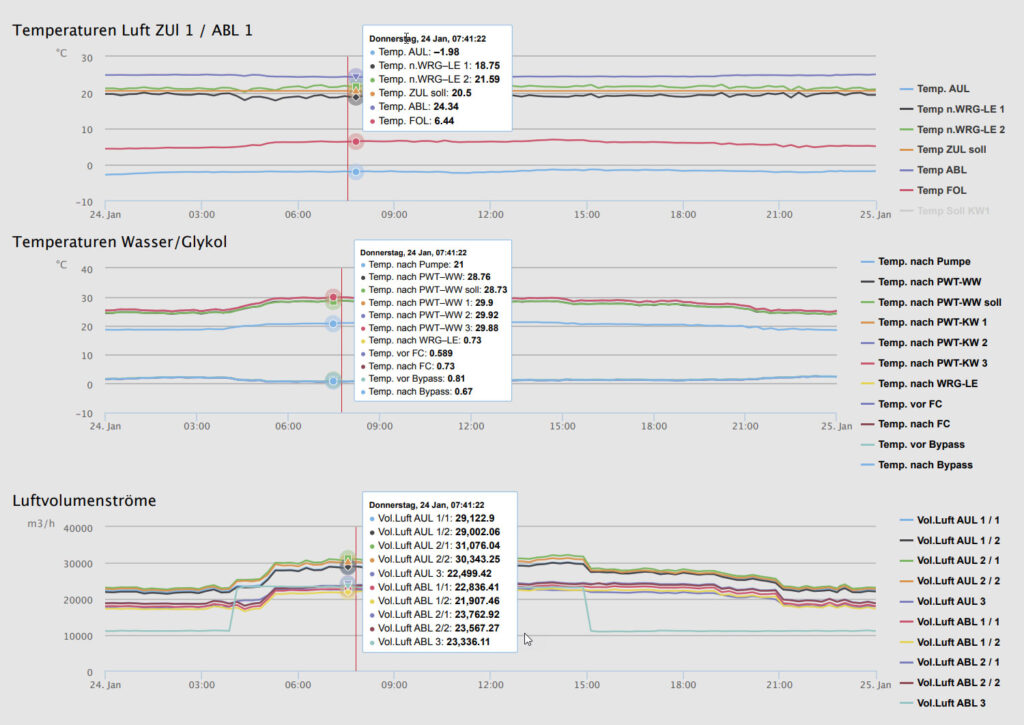

The efficiency of an ERS depends on a number of factors. The design and optimization of the system based on mathematical models early in the design phase is particularly important. Data such as the day to day use of spaces, the ERS applications, and the site-specific meteorological data are incorporated into the design process. By modeling the behavior of all system components and the operating characteristics of the heat exchangers, the values of peak performance and cumulative energy savings for a year are accurately calculated (Syskon design and optimization). When the system is in operation, the Konvekta controller can optimally control the system in any operating condition on the basis of these mathematical models and the extensive sensor data.

DATA-BASED CONTROL

Simple controllers, which control only the fluid circulation rate based upon the variable air volumes, typically fall short and are not able to achieve the potential of a closed loop system. The Konvekta Controller can precisely control even the most complex systems due to the comprehensive mathematical models and characteristic fields of all system components. The values correspond with the values determined in the design and optimization phase. The Konvekta Controller considers critical operating parameters in the control process to ensure maximum energy recovery under all operating conditions.

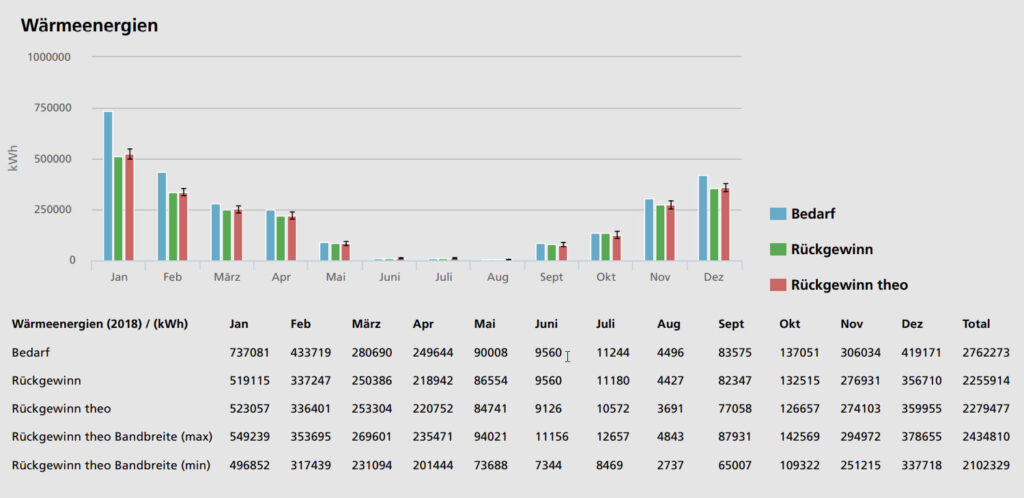

EFFICIENCY THROUGH CONTINUOUS TARGET/ACTUAL VALUE COMPARISON

Most ERS systems are not capable of reporting essential operating information such as malfunctions and efficiency losses. Simple comparisons between the SET point of the supply air temperature specified by the building control system and the ACTUAL temperature are not sufficient because the deficit is typically made up by the other heating or cooling sources. With this logic, the root problem remains undetected, which increases energy demand and operating cost, and energy efficiency cannot be calculated because the reference values are not available.

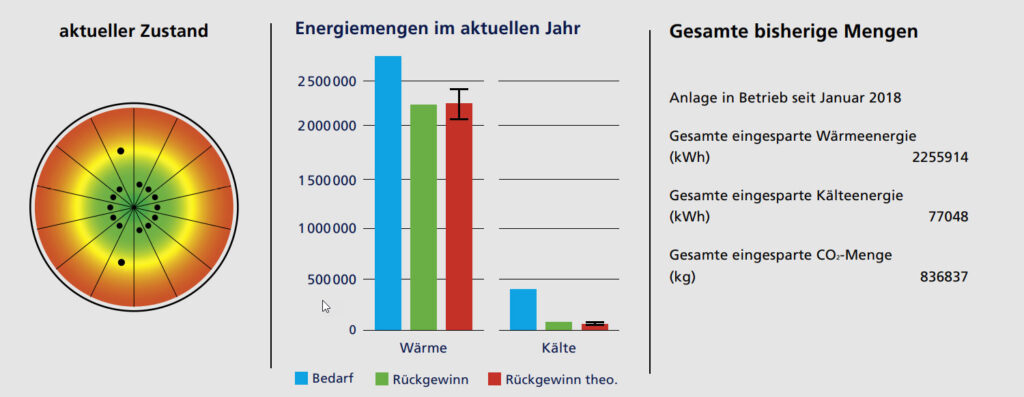

The Konvekta Controller continuously calculates the energy savings based on the actual measured operating conditions and displays it on the system dashboard. System problems due to deviations from the theoretical target values can be identified, and at the same time, the data can be used to calculate the system efficiency.

COMPLETE DATA TRANSPARENCY

The Konvekta Controller not only uses the operating data for its control processes, but also stores the data for later evaluation. With our comprehensive control system and archived data, actual operating values and incidents can be accessed and analyzed in detail at any time. Konvekta’s Controller will provide energy savings data in the historical data along with the theoretical target values. This information allows you to evaluate the systems efficiency in comparison to the original target values. The Konvekta Controller & Dashboard provide the necessary data for environmental certifications and confirm that the system is operating as efficiently as promised during the design phase.

THE KONVEKTA EYE

Detailed data is critical in terms of data transparency of the system. This data is helpful when investigating possible incidents. The analysis of this data requires time and know how since cause and effect in the system are not always obvious. The Konvekta Controller makes this process easier by determining aggregated states through which problems or deviations in certain system areas are immediately apparent. The data is displayed conveniently in a circular structure known as the Konvekta Eye. The Konvekta Eye displays real-time operating conditions and system status that can be seen in a glance. The Konvekta Eye provides immediate identification of operating issues that need attention. The Eye is customized for each system to display all critical operating parameters.

ADVANTAGES OF DATA MANAGEMENT

In summary, the data management of the Konvekta Controller offers the following advantages:

- Comprehensive operating data at a glance

- Permanent, automatic function monitoring

- Automatic error detection, including upstream and downstream systems such as the building hot water supply, supply air status and exhaust air humidification

- Automatic reporting of malfunctions

- Minimizes downtimes in the event of malfunctions by utilizing automatic error detection

- Quick reaction time in the event of malfunctions thanks to instantaneous reporting

- Maximum operating cost savings

INITIAL OPERATION OPTIMIZATION

All Konvekta systems are designed based on anticipated values during the design phase. Typically, design parameters are adjusted when the building is occupied. To compensate for this, Konvekta performs optimization of the ERS during the first year of operation. This maximizes energy efficiency for the actual use and operation of the building. This process also identifies any components that may have been damaged during the startup process so that they can be replaced or recalibrated

REMOTE ACCESS

All data can be accessed remotely using a VPN or Modem interface.