HIGHLY EFFICIENT HEAT EXCHANGERS

Konvekta’s uniquely designed heat exchangers are efficient, compact and sturdy. Because we both design and manufacture our heat exchangers, we can guarantee their performance.

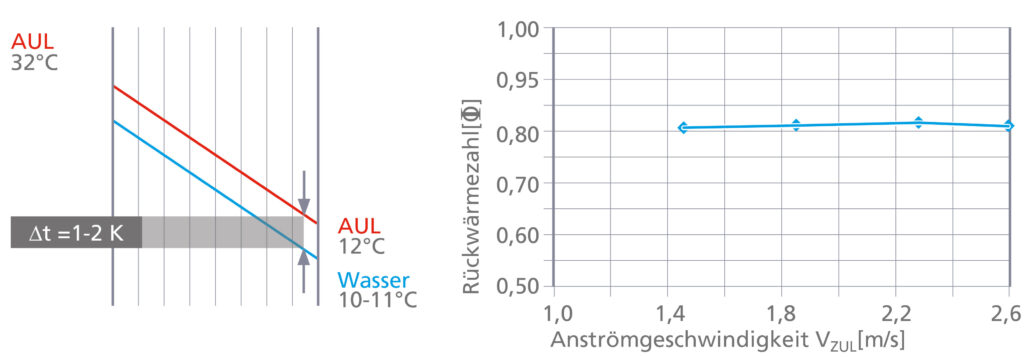

ALMOST PERFECT COUNTERFLOW

Konvekta heat exchangers are made of a unique design with headers on both sides. This achieves a cross-counterflow that is almost perfect counterflow. This design approach creates a large overlap of the leaving fluid and air temperatures and very small approach temperatures.

HIGHEST PERFORMANCE WITH MINIMAL HEAT EXCHANGER DEPTH

This is the prerequisite for achieving high temperature efficiencies (heat recovery coefficients) and optimum energy efficiency. This design approach allows minimal heat exchanger depths in the direction of the air flow. This saves space in the ventilation unit which saves cost. Konvekta heat exchangers are also exceptionally well suited for retrofit solutions, as their use allows excellent efficiencies to be achieved even in limited spaces. This is especially important if regulatory requirements and environmental standards must be met in a project.

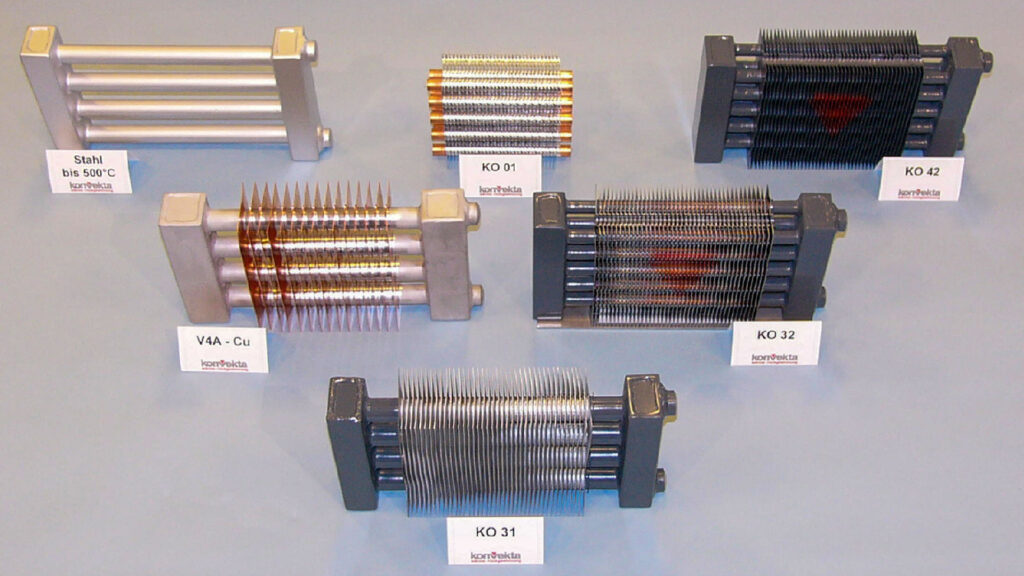

APPLICATION-OPTIMIZED DESIGN AND MANUFACTURING

During the design and optimization of the entire ERS system, with Syskon, the heat exchangers are designed for maximum recovery considering site specific conditions and seasonal climate changes. Due to flexibility in manufacturing and application-specific requirements, our heat exchangers are uniquely designed for each system.

When an order is placed, the heat exchanger design data is provided to the production department where the heat exchangers are manufactured exactly as specified for each specific application. Due to the high degree of automation in production, manufacturing is always consistent and precise.

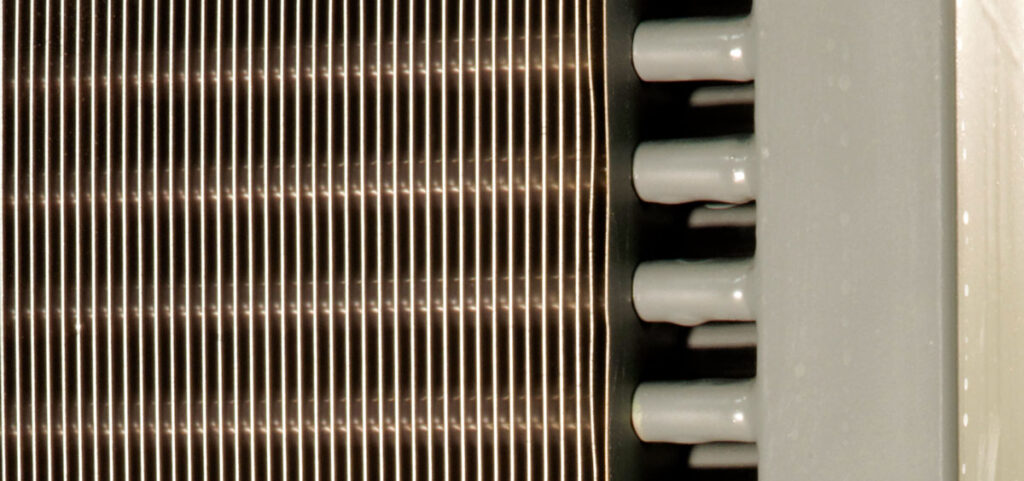

EXTRAORDINARILY STURDY

Depending on site conditions, the fins of the heat exchangers are made either of pure aluminum or of an aluminum/magnesium alloy; typically, with a fin thickness of 0.4 mm. These thick, stable fins not only increase the efficiency of the heat exchanger, but are also exceptionally sturdy, which is a great advantage, especially during transport, installation & maintenance.

CORROSION PROTECTION

The fins, made of an aluminum/magnesium alloy and their coating not only increases corrosion protection, but also reduces the tendency for fouling. The type of coating can be selected as required. In highly corrosive exhaust air conditions (such as in research laboratories or in fume hoods), Konvekta offers an extreme acid and alkali resistant coating. It has proven itself for over 20 years under extreme conditions.

CLEANABLE ACCORDING TO VDI 6022

Because of the stable and thick fins, Konvekta heat exchangers can be cleaned easily and thoroughly with high-pressure of up to 2,600 psi. Our heat exchangers can be cleaned without removing them from the air handler. The cleanability meets the requirements of VDI guideline 6022 and has been tested and confirmed by a 3rd party testing institute. This feature considerably simplifies the maintenance of the systems and increases the longevity.

The fact that the heat exchangers can be cleaned so easily and thoroughly makes them ideal as snow melt coils. Part of the heat exchanger is placed in front of the filter, which prevents high humidity in the filter medium. This is the most efficient and reliable way to prevent bacteria and mold growth on the air filters.

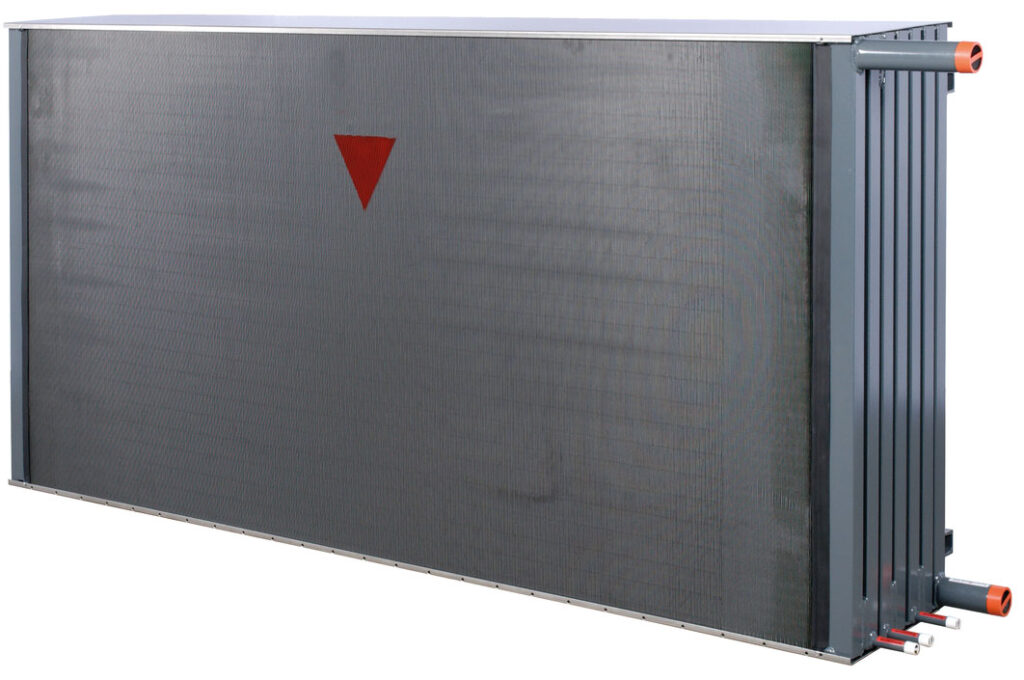

COMPATIBILITY WITH ALL AIR HANDLING UNITS

Konvekta is the technology leader when it comes to high efficiency energy recovery systems. This is where our company has expertise, innovation, and focus. The heat exchangers can be installed in all commercially available air handlers. This gives the client and the engineer flexibility in the project. They are able to use high-efficiency Konvekta systems in combination with the preferred air handler. Konvekta takes care of the coordination with the air handler manufacturer. After production at Konvekta, the heat exchangers are delivered to the air handler manufacturer’s factory, where they are installed in the air handling units. Flexibility without additional effort.

PROVEN PERFORMANCE AND GUARANTEED VALUES

The technical, as well as the economic data of the design and optimization of Syskon are precise and reliable. This also applies to the calculated temperature efficiencies/heat recovery coefficients of our heat exchangers. Konvekta guarantees the accuracy of these values and is also in a position to present corresponding verification from the independent laboratories of the Lucerne University of Applied Sciences and Arts. These studies prove that Konvekta heat exchangers are capable of achieving extraordinarily high temperature efficiencies/heat recovery coefficients of over 80%. In addition, independent follow-up measurements in systems have confirmed the accuracy of the performance values. Konvekta stands by its statements and design values. This reliability is fundamental in planning as well as in the operation phase. The Konvekta Controller provides a powerful tool for data verification with a multitude of operating data and analysis (see Konvekta Controller).