ERS multiple zone systems

In an energy recovery multiple zone system, multiple zones can be operated as needed by one hydraulic assembly and one water/glycol circuit. This allows numerous energy and economic advantages to be realized.

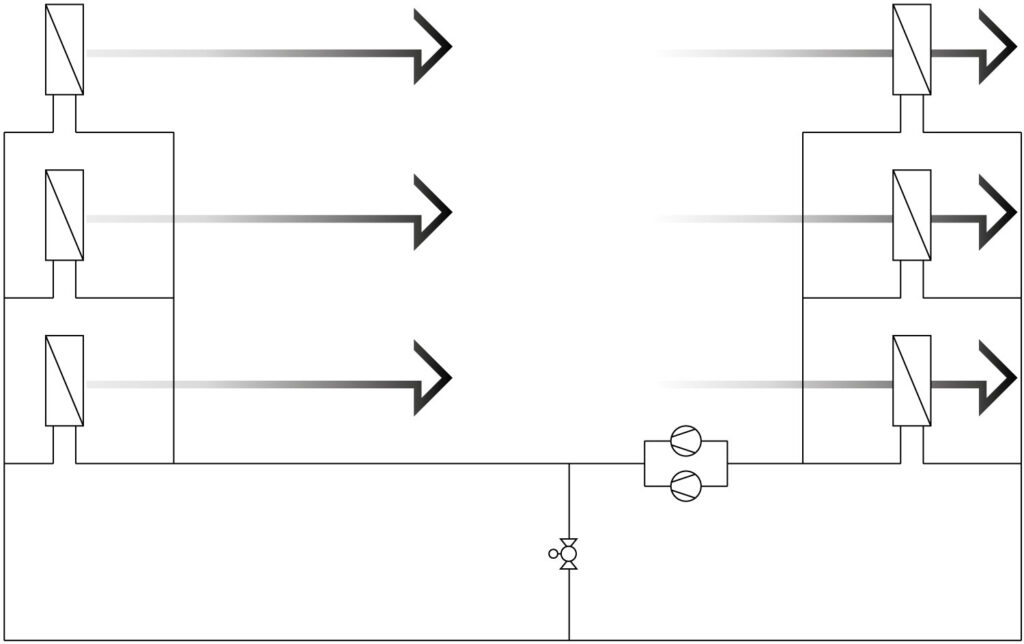

MULTIPLE SUPPLY AND EXHAUST ZONES IN A MULTIPLE ZONE ERS

Simple ERS systems with one supply air zone and one exhaust air zone transfer the energy from the exhaust air back to the supply air. If buildings have a large number of exhaust and supply air zones, this results in additional energy recovery possibilities. Several separate individual systems can be used in such buildings. However, significant advantages result from the use of multiple zone systems. In a multiple zone system, several heat exchangers in the exhaust air are connected to several heat exchangers in the supply air using a common hydraulic assembly and a common Konvekta controller.

ENERGY ADVANTAGES

The great advantage of multiple zone systems is that energy can be retrieved where it is available and brought to where it is needed, depending on the demand of each zone. Energy is added to the system only when the available energy in the system is not sufficient to meet the supply air temperature. Energy can be supplied centrally at the hydraulic assembly or locally in the respective zone. By doing this, the individual zones, although combined in a network, can be controlled individually depending on the building requirements.

STRUCTURAL ADVANTAGES

Consolidation to a single hydraulic assembly and a single Konvekta Controller not only saves costs, but also saves space.

TECHNICAL REQUIREMENTS

In multiple zone systems, a Controller is needed that uses the performance mapping of the heat exchangers and the characteristics of the valves and pumps. This enables the system to be controlled as efficiently and economically as possible.

Simply controlling the fluid flow rates through the individual heat exchangers as a function of the variable air volumes without taking into account the performance mapping will result in subpar performance.

The full potential of a multiple zone system is only realized if the variable operating conditions of all zones are taken into account. Accordingly, the Konvekta Controller must be able to control all interconnected zones during operation according to demand, both in full load and in partial load operation. To ensure this, the individual zone requirements are defined in the design and optimization phase in the Digital Twin process with the Syskon software and verified for all 8760 hours of the year. By doing this, the energy savings of the most complex systems can be maximized and accurately calculated.