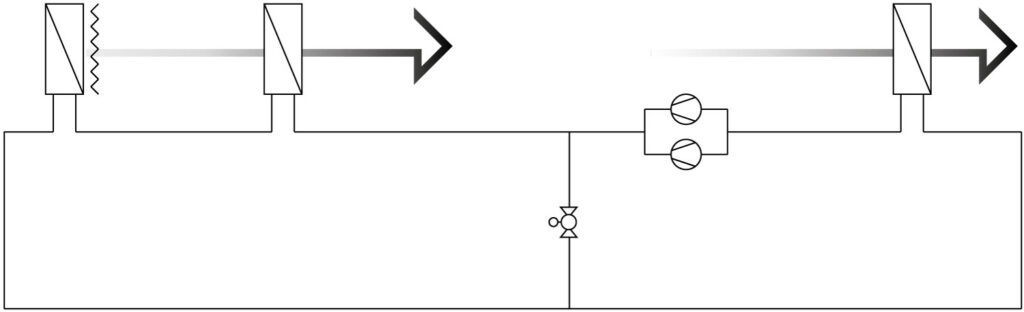

Filter preheating

To protect air filters from moisture, the heat exchanger can be divided, with one section placed in front of the filter as a filter preheat coil or snow melt coil. This is a very effective technique with the same energy efficiency as using one single heat exchanger.

SAFE MOISTURE PROTECTION

Filters in air handling units are typically in direct contact with outside air. They are sensitive to humidity, as damp filter media or silencers promote the growth of microorganisms and encourage mold growth, which can lead to contamination of the supply air. For this reason, VDI 6022 stipulates that air filters should not be operated with air that has a higher humidity than 90%.

USE OF FILTER PREHEATERS

Filters can be used as preheaters if the outside air is heated by about 2-4°F before the filter. This can be achieved by using a heat exchanger as a filter preheater upstream of the air filter.

Alternative methods, such as the addition of warm air, are not as reliable due to air stratification.

PROPERTIES AND CLEANABILITY UP TO 2,600 PSI

The following properties of the filter preheater are particularly important:

- Thick, stable fins (thickness 0.4 mm)

- Large fin spacing of 4 mm

- Narrow depth (maximum 180 mm)

- Easy to clean with high pressure wash up to 2,600 psi

NO LOSS OF PERFORMANCE

The use of a filter preheater does not cause any loss of performance in the ERS since it is a portion of the preheat heat exchanger. Therefore, compared to using one heat exchanger after the filter unit, there is no change in the amount of energy introduced into the supply air, nor in the air pressure drop of the entire system.