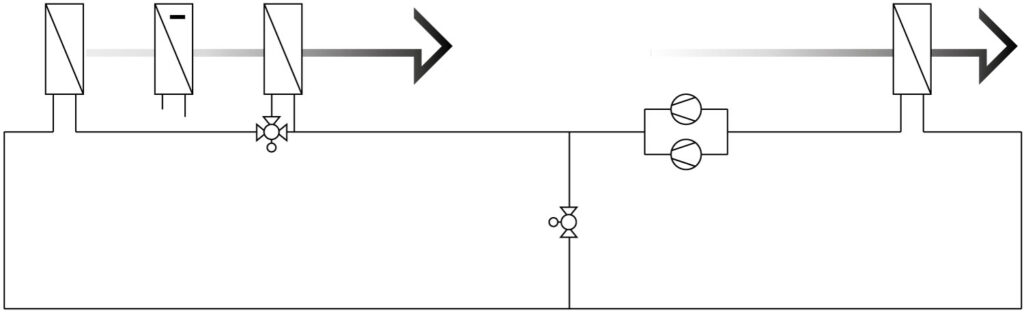

DEHUMIDIFICATION CIRCUIT (‘WRAP’-System)

The dehumidification circuit allows the absolute humidity of the supply air to be reduced to the setpoint during summer operation.

Efficient dehumidification

To dehumidify the outside air, it is cooled below the dew point temperature, which removes condensate. The dried supply air is then heated to the set temperature.

The cooling and dehumidification of the outside air can be done in two ways:

- on the air side using a cooling coil

- as part of a multi-functional ERS using a plate heat exchanger to cool the water/glycol loop

Optimal design

Typically, the cooling requirement is highest in humid conditions. The air must be cooled, dehumidified, and reheated. However, through use of energy in the ERS, the energy required for cooling and dehumidification is reduced to a minimum.

To achieve the highest possible efficiency at high outside air temperatures, building exhaust air is used to pre-cool the water/glycol mixture. This is then used to reheat the dehumidified outside air, which further cools the water/glycol mixture and increases the pre-cooling power of the ERS (“WRAP” design). The reheat energy is free!

Utilization of waste heat from the chiller

If the waste heat from the chiller is rejected using a second heat exchanger in the exhaust air, further savings can be achieved by eliminating cooling tower.

Dehumidification circuit with PWT-KW

Dehumidification circuit with KW-LK